200 m3 timber waste proves an ideal source of heat for Hogerhuis

Hogerhuis adopted the slogan ‘Building treehouses since we were VIII’ in 2011, when this specialist in treehouses and items of joinery for both indoor and outdoor use was established in Merelbeke. The brothers Bruno and Nicolas De Brabandere and their team of 40 employees have been creating the most magnificent masterpieces ever since. When the company’s workshop was destroyed in a fire on New Year’s Eve 2020, Hogerhuis decided to invest in new premises, and BIOSYNERGY developed an action plan to provide the company’s brand-new buildings with renewable, green heating.

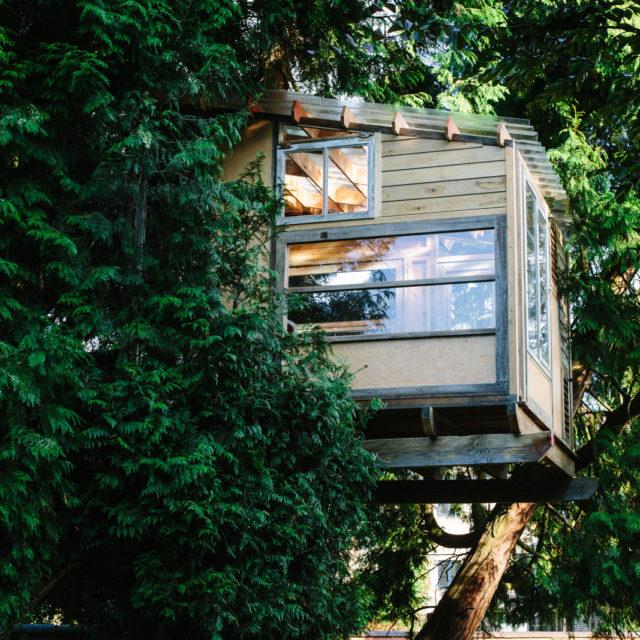

Beautiful wooden treehouses, annexes and tiny houses

From foundations to doors and windows and even perfectly finished interiors, Hogerhuis creates the most beautiful wooden items in its workshop. Treehouse builder Nicolas De Brabandere: ‘We generate around 200 m³ timber waste every year. Previously, we had to pay for a waste disposal company to collect this from our premises, while we also had to pay our heating bills.’ When BIOSYNERGY heard that Hogerhuis was planning to build new company premises, they got in touch with the woodworking company immediately.

Consideration for nature and the environment

Based on the architect’s plans, BIOSYNERGY analysed the timber waste flows generated by Hogerhuis’s production. What did they discover? The waste flows were large enough to justify the drafting of a plan for an environmentally friendly biomass boiler. Nicolas continues: ‘We specialise in wooden joinery, so nature conservation and sustainability are very important to us. That’s why our new building fully satisfies the requirements imposed by the Flemish government on the energy performance and indoor climate of buildings. BIOSYNERGY’s proposal to valorise our timber waste by converting it into renewable energy for our underfloor heating system was very interesting.’

A single biomass boiler is enough to heat the entire building

In collaboration with the brothers, BIOSYNERGY prepared a file to submit in response to the ‘Green Heat Call’, a campaign initiated by the Flemish government to provide selected projects with financial support. After a thorough examination of all ecological, technical and economic aspects, the Flemish Energy and Climate Agency approved the file. ‘The timber waste and dust we generate from our woodworking operations are collected in a silo. This is then conveyed to the biomass boiler, and used to heat water to the desired temperature. The boiler controls the underfloor heating in our workshops, ensuring that it’s always warm enough for us to work comfortably.’ Although this is a cheap and green way to heat a building, an ecologically friendly heating system like this requires a substantial investment. Nevertheless, Nicolas acknowledges that converting timber waste into green heat is an excellent and interesting alternative.

Smooth coordination and perfect after-sales services

According to Nicolas, all aspects of Hogerhuis’ cooperation with BIOSYNERGY, including the engineering, coordination and implementation of the project, ran very smoothly indeed. ‘We have a very pleasant working relationship with BIOSYNERGY. The company’s after-sales services are also outstanding. If we detect a malfunction or some settings need to be adjusted, all we have to do is give them a call. They are here in a jiffy to resolve the issue.’ Furthermore, BIOSYNERGY always ensures perfect compliance with all statutory regulations on biomass boilers. This means that Hogerhuis, in turn, can be assured of being able to heat its premises safely and sustainably, without any worries, now and in the future.

"As a woodworking company, a biomass boiler system is a wonderful and interesting solution for sustainably heating our premises with our own timber waste flows. Our collaboration with BIOSYNERGY ran very smoothly indeed and they provide us with outstanding after-sales services, even today. If we detect a malfunction or some settings need to be adjusted, all we have to do is give them a call. They are here in a jiffy to resolve the issue."

Nicolas De Brabandere